QVC-5 Vacuum Conveyor

The QVC-5 pneumatic vacuum feeder utilizes compressed air to generate a high vacuum via a vacuum generator for material conveying, eliminating the need for a mechanical vacuum pump. It offers advantages such as a simple structure, compact size, maintenance-free operation, low noise, convenient control, elimination of material static electricity, and compliance with GMP requirements. It serves as an automatic feeding device for machinery such as tablet presses, capsule fillers, dry granulators, packaging machines, crushers, and vibrating screens.

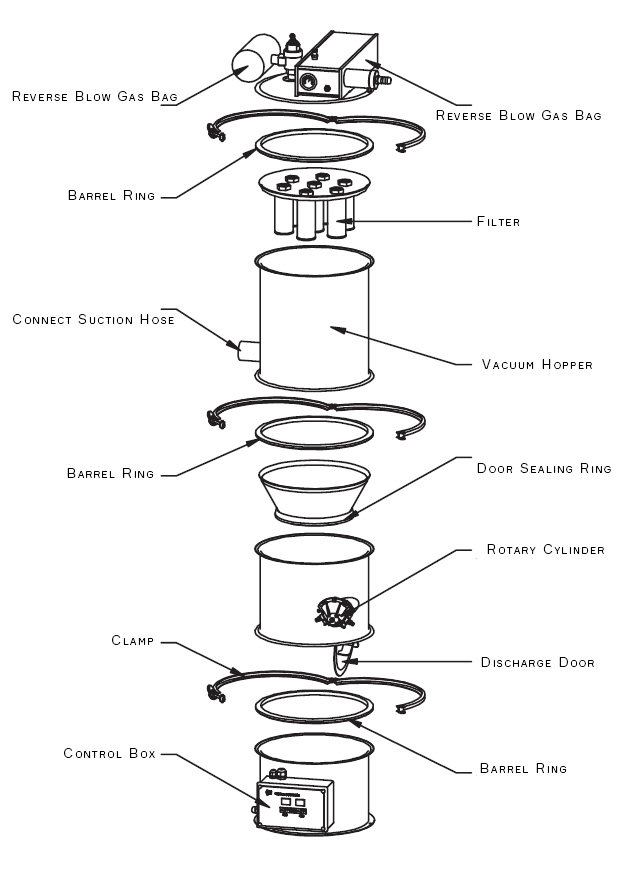

When compressed air is supplied to the vacuum generator, a negative pressure is created, forming a vacuum airflow. The material is sucked into the suction nozzle, forming a material-airflow mixture, which travels through the suction pipe to the feeder’s hopper. The filter separates the material from the air. When the hopper is full, the controller automatically cuts off the air supply, stopping the vacuum generator. Simultaneously, the hopper door opens automatically, allowing the material to fall into the equipment’s feed hopper. At the same time, compressed air automatically cleans the filter via a pulse backflush valve. The feeder restarts automatically when the set time is reached or when the level sensor sends a feeding signal.

| Model | Conveying Capacity | Hopper Volume | Working Pressure | Compressed Air Consumption |

| QVC-5 Pneumatic Vacuum Feeder | 900~6000 kg/h | 60.0 L | 0.4~0.6 MPa | 2880 NL/min |