ZKS-20-5 Vacuum Conveyor

The vacuum feeder produced by our company is a vacuum conveying equipment for powdered, granular, and powder-granule mixed materials. It can automatically transport various materials to the hoppers of equipment such as packaging machines, injection molding machines, and crushers, and can also directly deliver materials to be mixed into mixers (such as V-type mixers, two-dimensional mixers, three-dimensional mixers, etc.). This reduces the labor intensity of workers and solves issues such as dust overflow during loading. It is an ideal equipment for pharmaceutical and food factories to pass “GMP” certification and promote clean, civilized production.

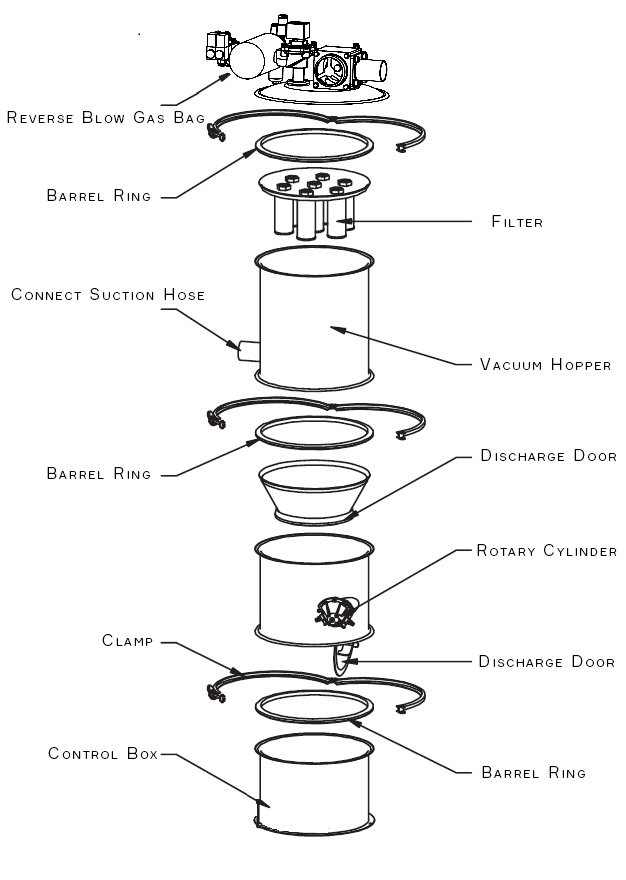

The vacuum feeder consists of a vacuum pump (oil-free and water-free), a vacuum hopper, filters (with multiple options including PE filters, 316L stainless steel filters, or titanium filters), a compressed air reverse blow device, a pneumatic discharge door device, an automatic level control device, a stainless steel suction nozzle, and conveying hoses. The entire system is reasonably designed and exquisitely manufactured.

| Model | ZKS-1 | ZKS-2 | ZKS-3 | ZKS-6 | ZKS-7 | ZKS-10-6 | ZKS-20-5 |

|---|---|---|---|---|---|---|---|

| Compressed Air Consumption | 10 NL/min | 10 NL/min | 10 NL/min | 25 NL/min | 25 NL/min | 50 NL/min | 50 NL/min |

| Motor Power | 1.5 kW | 2.2 kW | 3 kW | 5.5 kW | 7.5 kW | 7.5 kW | 11 kW |

| Filtration Accuracy | 0.4μm, 0.5μm, 5μm, 10μm | ||||||

| Conveying Capacity | 400 kg | 600 kg | 1200 kg | 3200 kg | 6000 kg | 6000 kg | 5000 kg |

| Note: | The conveying capacity is measured with a 4-meter conveying pipe length and using flour as the material. Longer pipe lengths will reduce the capacity, and the capacity is also highly dependent on the characteristics of the material. | At 10 meters conveying distance | At 20 meters conveying distance | ||||